This article is more than 1 year old

At 9 for every 100 workers, robots are rife in Singapore – so we decided to visit them

They're guiding kids through museums, moving food in mega-kitchens – and cleaning where you can't see them

Feature Robots largely remain the stuff of trepidation and speculation – but in Singapore they've suddenly become very easy to find.

As the island nation state emptied out over the holiday season as borders finally reopened for the first time since the pandemic began, I decided to spend the time meeting Singapore's bots rather then deal with the hassles of international travel during a plague.

I started with "TEMI", the autonomous tour guide at the country's National Gallery, described [PDF] by the art museum as "an alternative experience especially catered to visitors who have missed guided tours when visiting the Gallery."

When approached, the waist-high TEMI cheerfully greets visitors before rolling off in the direction of art it thinks you need to understand better, and offering audible titbits of information along the way.

On my visit, children followed the robot around like it was the pied piper. At least they did until they were led into a room they didn't have the proper entry clearance for. A reprimand was issued by a human attendant along with instructions to acquire the proper colour-coded sticker for entry into that gallery. Maybe TEMI needed better programmers?

TEMI is more than just a customised National Gallery tour guide, however – other units of its off-the-shelf robot models have been repurposed towards less educational ends.

This temi robot is obsessed with the Squid Game 😱#SquidGame#thesquidgame#squidgamenetflix#squidgamechallenge#SquidGame#SquidGamememes https://t.co/RvdJKolhxy pic.twitter.com/ts7A8XBOiV

— Temi (@robotemi) October 7, 2021

Shortly after the museum visit, reports came in that Singaporean superapp Grab was road testing a food delivery robot vehicle on the city-state's island getaway of Sentosa.

On Sentosa today. @GrabSG food delivery robot getting road test pic.twitter.com/HMG3laCZsl

— Daniel Moss (@Moss_Eco) November 26, 2021

It immediately went on the tour wishlist.

Robots, robots everywhere

Singapore's robots are ubiquitous. They work in food and beverage settings as info counter attendants, in hotel services, as security guards, in hospitals, on vertical farms, out to sea staffing a cruise ship, and even in the 200 acres of botanical gardens cutting grass at night while Singapore slumbers.

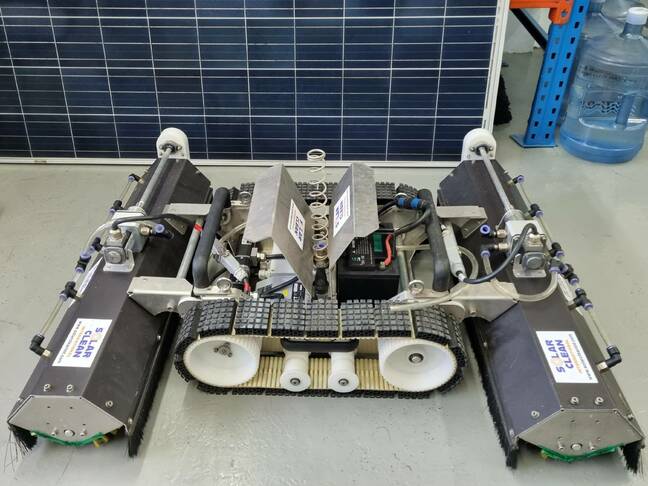

Many of Singapore's solar panels are now cleaned by robots, an important application because the nation is already home to over 4,000 private or government solar installations and planners want to take advantage of the sunny weather to quadruple solar energy production by 2025.

Among Singapore's plans are a floating solar panel the size of 45 football fields to assist in achieving that goal.

All together, it makes for a lot of solar panels to clean.

A visit to the office of Solar Clean International (SCI) revealed the machine that does the job: an off-the-shelf remote-controlled vehicle equipped with two motors, a water tube, and brushes.

"The motivation for using robots to clean solar panels is for safety and ethics as well as quality," SCI director Rob Wilkins told The Register. "For one thing, these robots clean uniformly. A solar panel investment can be like a mortgage, and you want to protect that investment by maintaining it. Secondly, labour costs to do this by hand might be cheap, but is it ethical to have a worker up on a roof like that? What if they were to fall?"

My timing leaving Wilkins' office was impeccable as I ran into a cleaning robot in the subway station. Like many of the robots I encountered, this one was an off-the-shelf device from a company called Avidbots designed to do a job once accomplished by lower-waged workers. The bot had a cutesy design with drawn-on arms and digitally lit-up eyes making it seem less imposing. When I spotted the bot it was stationary and parked inconveniently in the middle of a pathway, drawing attention from curious bystanders.

According to the manufacturer's website, the cleaning robot was more than an anthropomorphic outsized Roomba. It contained an AI platform that maps out the facility and generates a customisable cleaning plan. Onboard sensors detect any changes which are thus automatically modified.

"By interpreting long-range lidar sensor data and taking advantage of large and detailed cleaning maps, the Avidbots AI Platform provides location level awareness to Avidbots robots. This means Avidbots robots understand their location relative to items in their immediate vicinity as well as in a wider context, such as where they are in a large facility," explained the robot maker's website.

Next up on the tour: A robot librarian

"This is part of our ongoing efforts to tap on technology to provide convenience to our patrons, reduce manual labour processes for our staff, and enhance our overall service delivery," the National Library Board (NLB) Deputy Chief Information Officer, Rama Narayanan, told The Register of the two types of robots first deployed in Singapore's libraries in 2018.

The first type is a shelf-reading robot. These machines work after hours scanning RFID-tagged books on shelves and making a list of misplaced items for the human staff to relocate in the daytime. Narayanan said having 13 machines across eight libraries saves the NLB approximately 3,500 hours of labour a year, covering about 50,000 books overnight.

In the northeast of the island, the Tampines Regional Library operates the other type of robot, a mobile book deliverer. The machine's path starts at the library entrance where it auto-processes borrowed items returned into its receptacle. When the bin is full, the robot follows a path of reflective strips along the floor until it reaches a sorting room. There it alerts staff to replace its bin and send it on its merry way. The entire process from library entrance to sorting room back takes less than 10 minutes, with the librarian able to change the bin in around two minutes time.

The book drop makes about 20 round trips each day, returning 5,000 books to the sorting station and reducing the manual labour required of staff while improving workplace safety, said Narayanan.

In the future, NLB hopes to have robots that assist patrons more directly, for instance by guiding them to the right shelf, surely a win for the 63 per cent of introverted librarians out there.

As for that original Grab food delivery vehicle that piqued my interest, it wasn't available to view on the streets, but the company would show me the robot deployed at their food outlet "GrabKitchen" – a facility that some describe as a "dark kitchen" as it houses multiple kitchens for different outlets, all of which share a single location that allows Grab to deliver at higher speed.

Even after the post-lunch rush, the place was hopping with Grab's green-shirted delivery drivers, and that thriving demand was where and when the Keenbot, a SoftBank and Keenon Robotics collaborative robot, showed its value.

While the Keenbot is a front-end robot waiter in some use cases, Grab uses theirs on the back end as a replacement for a bus boy or internal food runner. The machine travels a programmed path between food stations, collecting the items required to complete an order. The robot simply shows up and a worker places freshly-cooked items on its trays. At its final destination, a human worker passes the completed order to a Grab delivery driver.

The machine seemed from the outside more reminiscent of a mobile conveyer belt than a robot, albeit a conveyor belt equipped with obstacle avoidance, auto speed adjustment and anthropomorphized features like big eyes that blink, and a kawaii-esque chirpy personality. It had the personality of a pleasant coworker, as long as you have had your morning coffee.

After viewing a video of operations, a friend said: "I doubt they are faster than the Aunties and Uncles," referring to the older population often seen diligently bussing tables in Singapore's hawker markets.

From the get-go, SoftBank and Keenon Robotics have insisted that the Keenbot wasn't designed to replace workers, but rather to allow existing workers to be more customer-centric and thrive in roles that humans do best.

"With the current disruption from the pandemic-induced lockdowns, technological adoption in the form of robotics by businesses will transform tasks, jobs and skills," promised a canned statement released at the machine's debut.

Getting philosophical

Seeing these bots in situations once filled by humans reminded me that the machines may not be about to go full Terminator, but job losses hit hard. Management consultancy McKinsey, for example, has warned that this continuing automation could mean more than 100 million workers could be displaced from their occupation by 2030.

Yet the bots I saw in Singapore were nowhere near independent operations – they need lots of human assistance or oversight.

Navinda Kottege, group leader for robotics and autonomous systems at Australia's Commonwealth Scientific and Industrial Research Organisation (CSIRO), has previously told The Register this is the way it's going to be for some time. Kottege said "low-level autonomy" robots will dominate because humans prefer to remain the main decision makers, at least while the technology is not good enough to give us graceful performance with minimal mistakes.

Which raises the question of whether the machines I saw are actually robots. Is a remote-controlled solar panel cleaner a robot, or a mobile machine that performs specific tasks? If so, what about a remote-controlled car? In 100 years would our descendants view a drip coffee machine as an early robot barista?

"It's not an easy question," Eureka Robotics CEO and Nanyang Technology University (NTU) professor Pham Quang Cuong told The Register about the line between robots and automation.

"A robot is multipurpose versus automation which is single purpose. Robotics is using multi-purpose equipment tailored to specific task." Pham reckoned that mostly all of the devices on the tour qualified as robots, albeit some as teleoperated ones.

Comparatively, the International Organization for Standardization (ISO) defines a robot as an "actuated mechanism programmable in two or more axes, with a degree of autonomy, moving within its environment, to perform intended tasks." The ISO also specified that robots fall into the classification of industrial robot or service robot according to its intended application.

Workforce shortages and other reasons for adoption

For all the service robots visible, it turns out Singapore has a lot more robots out of sight, hidden from the public eye in places like production lines. CNN reported that the city-state had the highest adoption rate of industrial robots anywhere in the world, at nine per 100 workers.

According to the International Federation of Robotics (IFR) [PDF], Singapore installed 5,297 robot units in 2020 alone, the high density largely due to the electronics industry.

More robots can be expected as the government encourages their adoption. One government initiative provides up to 80 per cent of funding for construction companies to adopt automation and robotics as the industry suffers from a prolonged workforce shortage.

Studies have shown that robot use in countries is predominately driven by labour shortages. In Singapore, these can be attributed to border restrictions in the COVID era, and ageing populations.

In Singapore much of the manual or construction labour it's hoped robots will perform have typically been done by foreign workers, which a good portion of the country's leaders have expressed a desire to reduce.

In an address speaking about a government robot initiative, Minister of State for National Development Tan Kiat How said:

We all know there are a lot of misconceptions about what it means to work in the construction industry and the built environment sector – social expectations, social stigma that work in the sector is dirty, demanding and dangerous.

Tan recognised this perception needed to change and thanked those growing the industry talent pipeline of actual real humans. However, he expressed the desire for the actual real humans to take on different tasks and leave some stuff to the robots, much like the corporate sentiments spoken by Keenon and SoftBank.

On the march, out of sight

According to research firm Robo Global, even without the workforce shortages, digitisation in the global pandemic has created fresh demand for automation bolstered by consumer demand and supply chain strain that make employing robots in places like the manufacturing line necessary.

"Asia as a whole is such a high-volume manufacturing centre, so robots will be most concentrated here," Pham told The Register.

Indeed, the IFR called Asia the world's largest industrial robot market and reported its average robot density grew by 18 per cent CAGR from 2015 until 2020.

Pham himself has an interesting tale. His engineering breakthrough occurred when he, along with other boffins, designed a robot that could assemble an IKEA chair in just 20 minutes and 19 seconds, thereby proving that robots can be trained to do tasks that require considerable dexterity and can enrage and/or frustrate humans.

These days, Pham's company Eureka Robotics creates robots for use in the manufacturing industry. Many of his clients are in optics. He refers to his robots as "high accuracy and high agility," meaning they don't just do one motion over and over, but rather they adapt and can detect a moved position to 0.2mm accuracy.

His work once focused on delivering a full machine before it transitioned into providing the software and working with system integrators in places like China. The future, he believes, is serving larger partners all over the world by moving his product to the cloud. He feels his company can accomplish this by 2023.

As for the service robots, Pham said: "Self-driving robots is one of a kind. But robot waiters, baristas, disinfection robots – how sustainable is that? Is it a showcase or a real kind of massive deployment of robots in the future? I don't know. What is sure is industrial robots are huge." ®